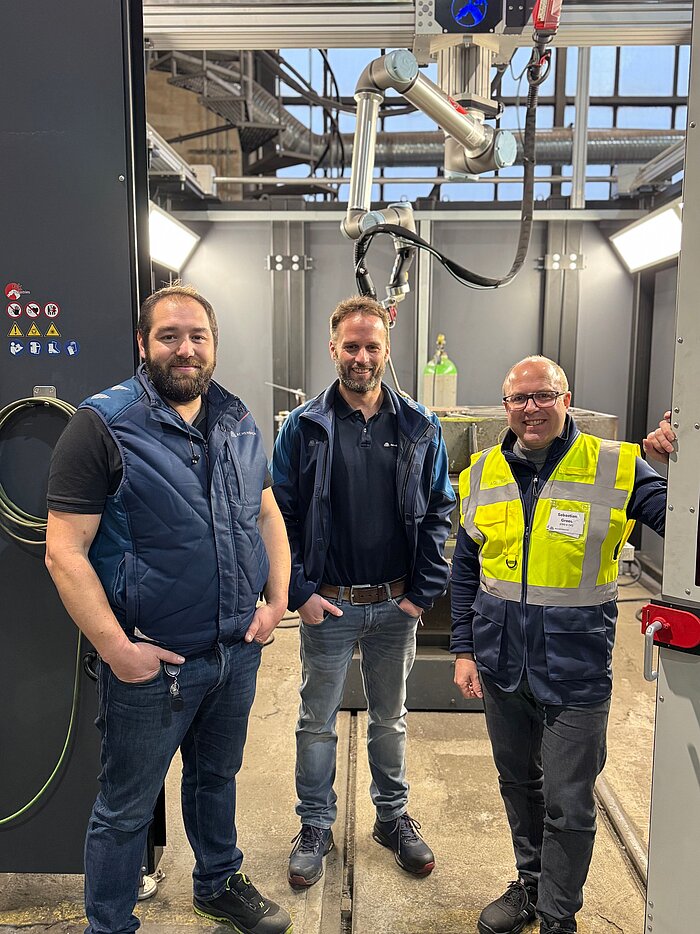

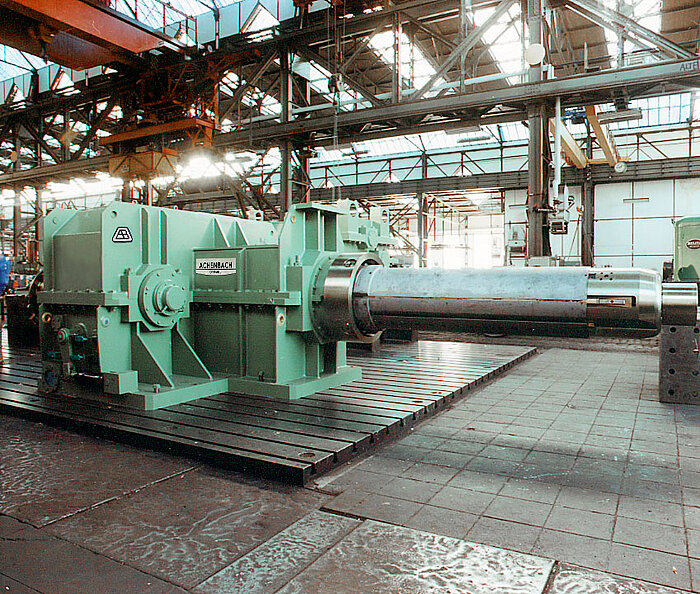

After successfully upgrading The San Marco Foil Rolling Mill at @Carcano last year, we are pleased to have received another order from our longstanding customer and partner for the modernization of a further foil rolling mill (Spluga line) built by Achenbach in 1979 to most modern standards. The order comprises essential components for improving quality and productivity. Among other features, this includes, for example, the innovative Achenbach Uni Heat® Curved Hot Edge System to optimize strip flatness at the edges, an Achenbach UniMark® Roll Mark Detector for early detection of foil surface defects as well as the highly efficient Achenbach UniDry® rolling oil blow-off system for evenly dry strip surfaces. Moreover, the complete Achenbach OPTIROLL® i3 package for rolling mill automation along with an Achenbach UniFlat® Flatness Measuring Roll will allow high-precision strip flatness control. In addition to the upgrade, Achenbach will also supply Carcano with a new Achenbach SUPERSTACK® II Filtration System for micro-filtration of the cooling lubricant.

Carcano has further commissioned Achenbach to carry out the repair of the damaged cold rolling mill after an extensive fire damage. While the rolling mill will be put back in operation by October this year, a more extensive refurbishment will be completed in a second step in August 2026. We would like to thank Carcano for the renewed trust and for the long term partnership and are looking forward to continuing our cooperation on these projects, which once again demonstrate Achenbach´s understanding of the product – a commitment to maximum availability throughout the entire operating life. Achenbach machines are sustainable per se and designed to deliver top performance for decades.