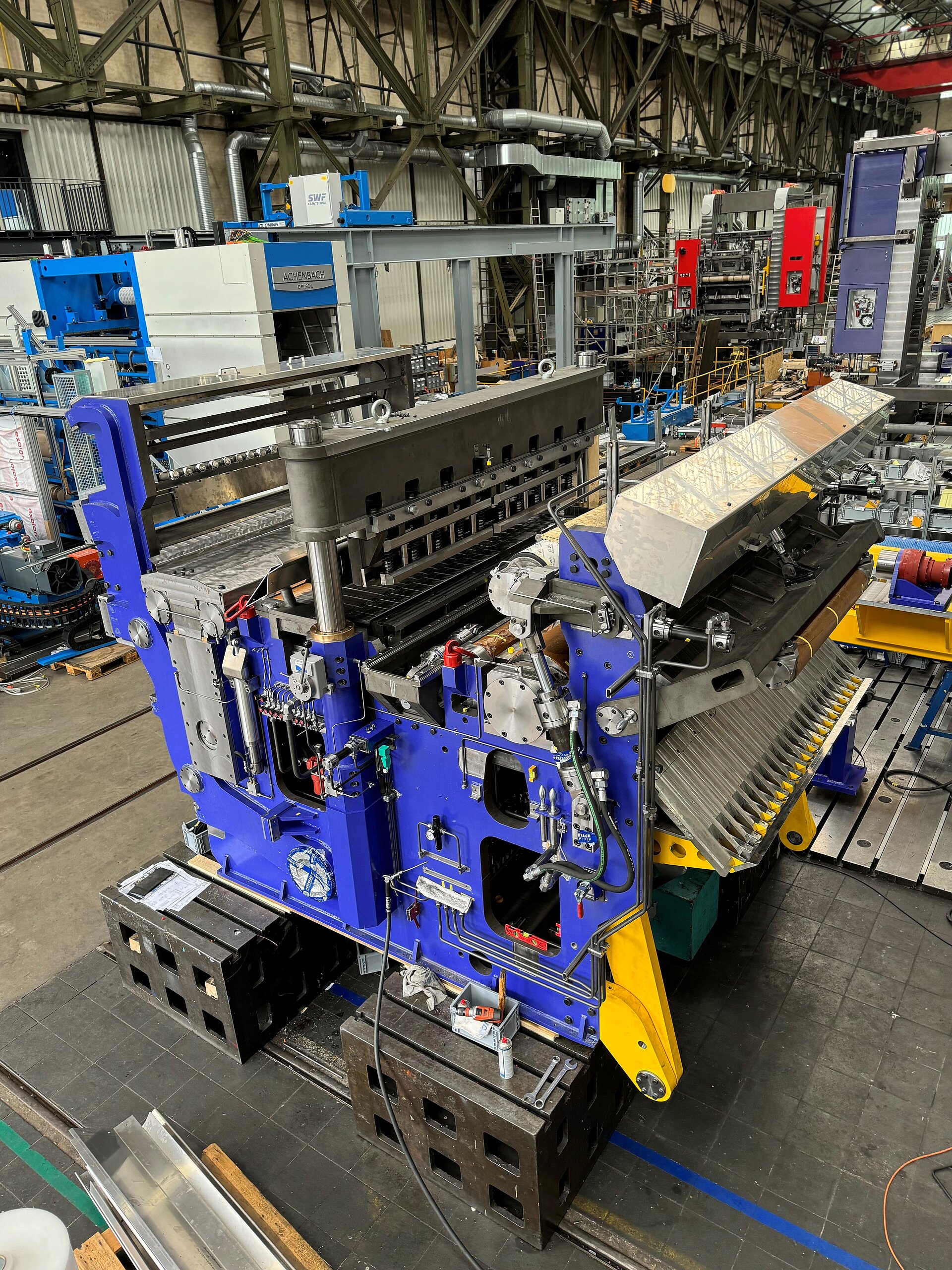

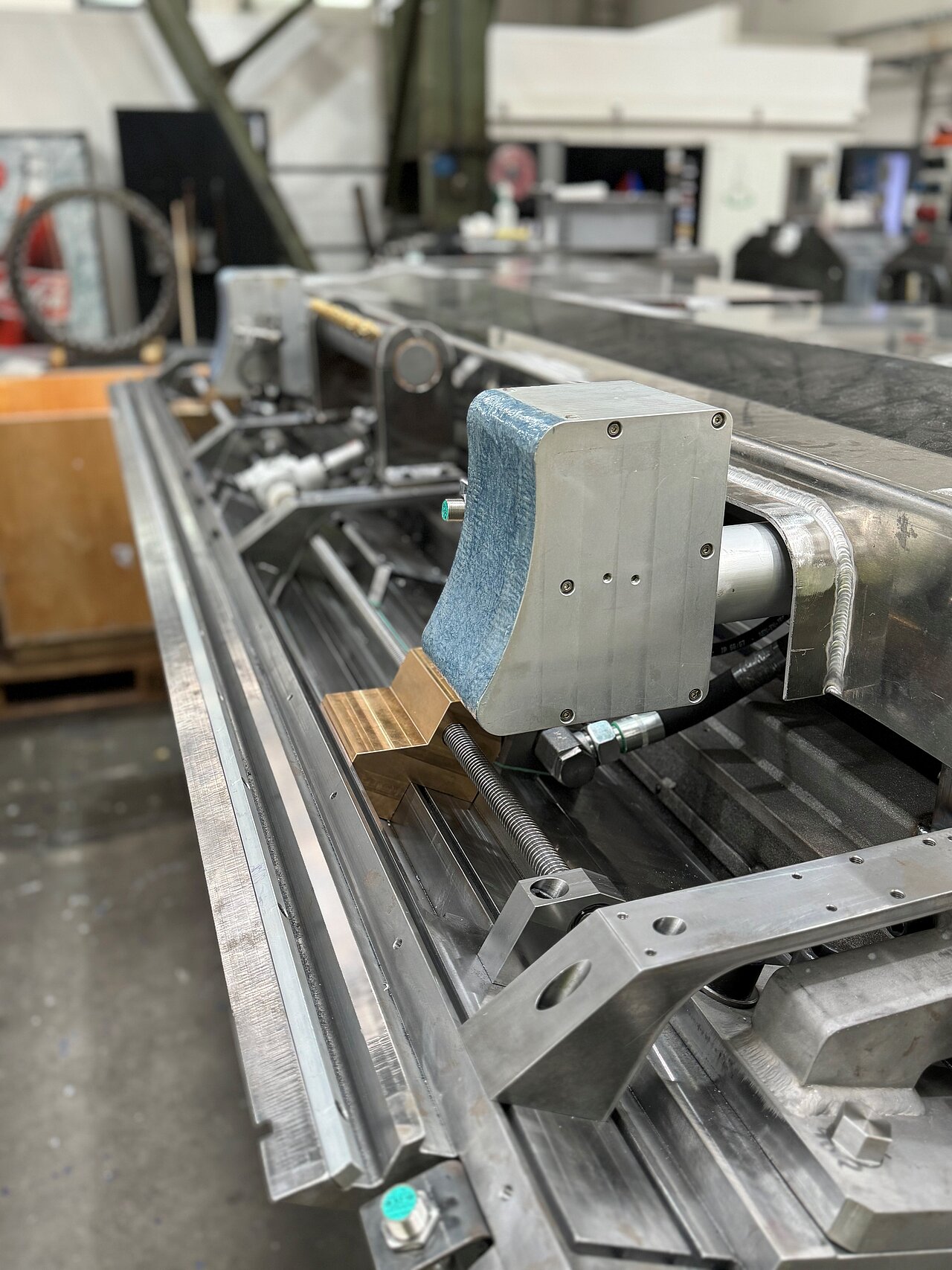

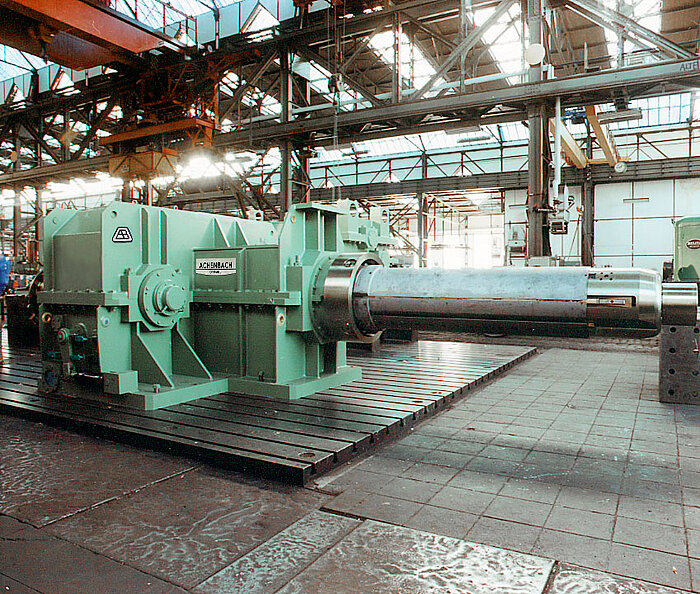

Not only in foil production, but also in strip rolling, customers are ideally positioned if they opt for Achenbach technology. An Achenbach OPTIMILL® 6-high Strip Rolling Mill is currently being built in our workshop, impressing with extraordinary technical performance data in terms of rolling force, rolling torque and drive power. The entry guide is characterized by a compact and rigid design with fully integrated spray bars and feeding lines. Sustainable design features such as special energy-efficient fume hoods and the inductive Achenbach UniHeat® Curved Hot Edge System are also implemented. This highly efficient and robust system is fully integrated into the spray plate and exit guide design to effect both top and bottom work roll. Finally, the new strip rolling mill combines the Achenbach OPTIROLL® MillModelling process simulation with adaptive pass calculation and the cloud-based analysis system Achenbach OPTILINK® for continuous improvement setting the course for a new era of digital supported rolling.

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.