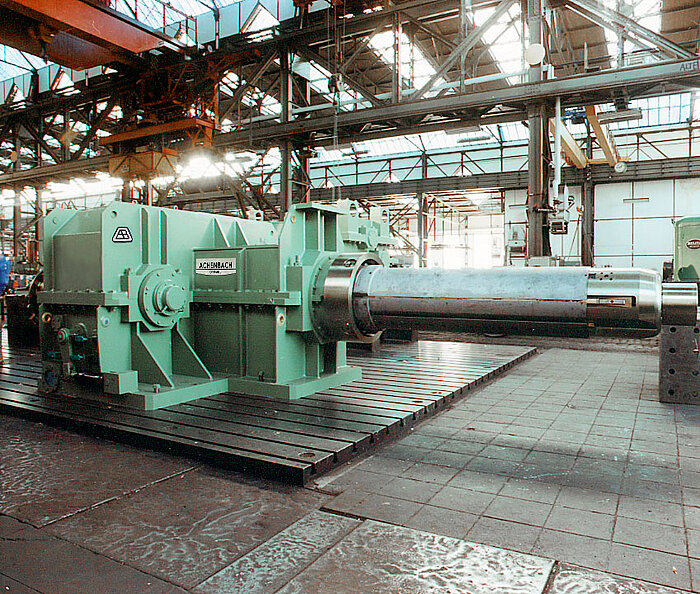

Achenbach has recently received an order from Hindalco for targeted UniSkill Process Consulting to improve the production results on a foil rolling mill at the Mouda site. With the aim of rolling the thinnest foil (down to 6.5 µm) in the best quality, experts from Achenbach will train the operators with customized on- and off-site trainings and consolidate the quality-improving measures in the process. Previously, Achenbach has already supported Hindalco successfully by carrying out a complete measurement and realignment of the foil rolling mill, in fact a third-party machine. We are very pleased that the foil manufacturing leader trusts Achenbach's expertise when it comes to process optimisation. In the area of Achenbach Life Cycle Support customers are increasingly making use of our focused consulting service to improve and foster their foil production process.

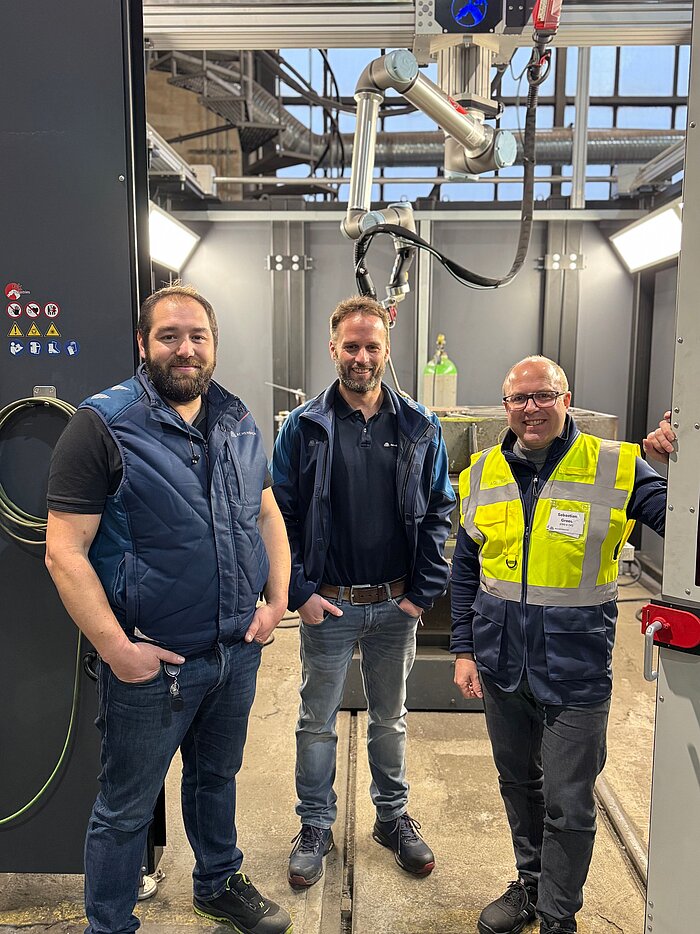

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.