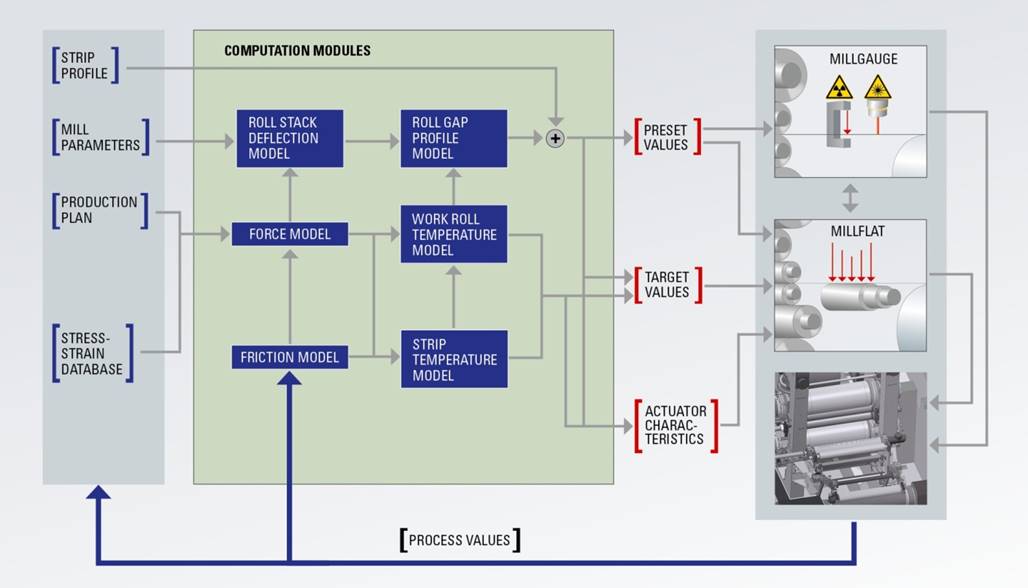

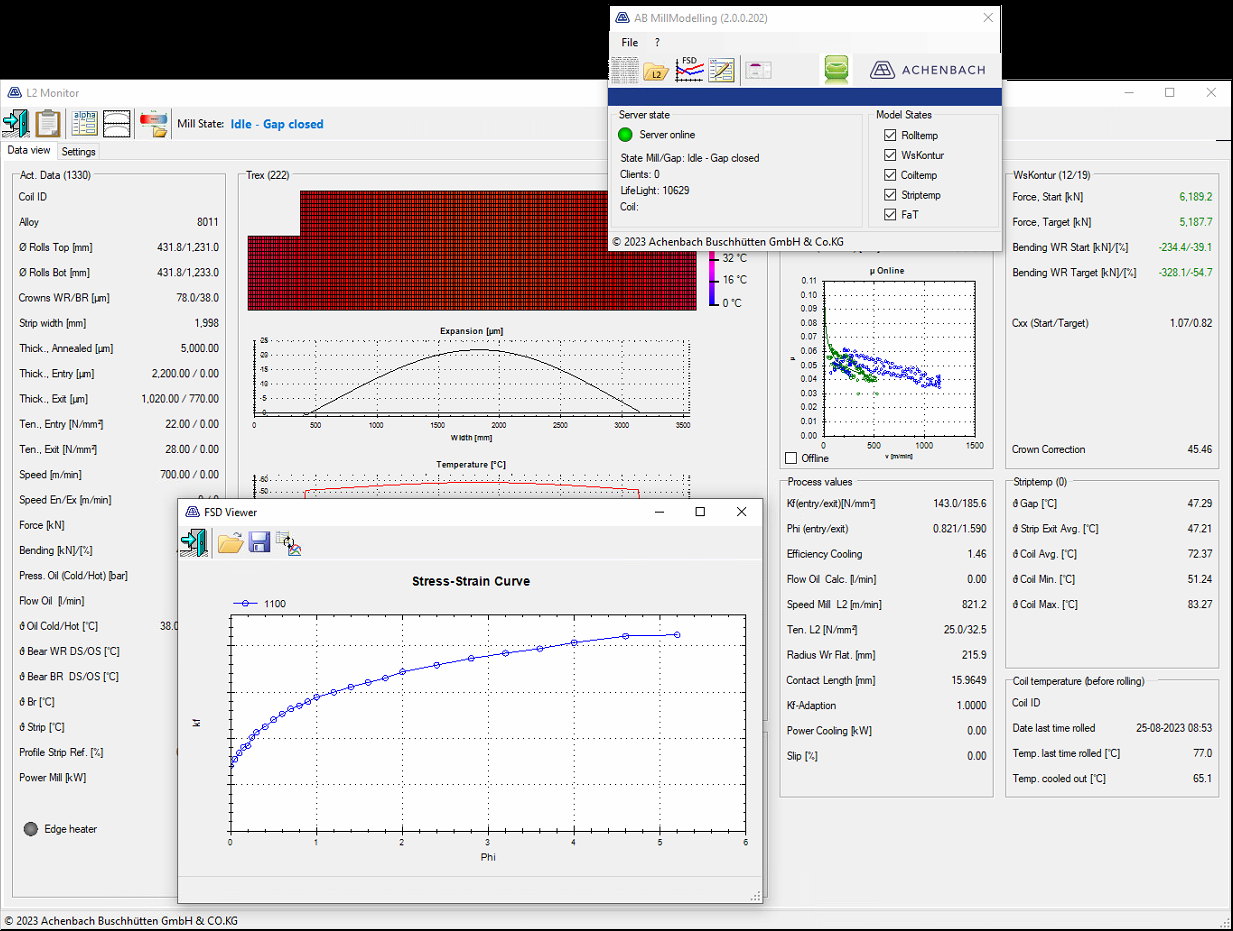

We have successfully implemented our Mill Modelling process simulation on a rolling mill at our customer Hindalco. As a further component of the Achenbach OPTIROLL® i3 Rolling Mill Automation, it ensures best presetting, optimal presentation of all actuator characteristics as well as narrowest tolerances even in transient rolling phases. Based on extensive process models, roll force and friction in the roll bite, the thermal expansion of the work roll, the deflection of the roll stack, the temperature of the strip in all phases of rolling as well as the sensitivities of the flatness control actuators can be calculated. In this way, these can be preset for the upcoming process and guaranteed tolerances can be achieved more quickly, since a corresponding measurement of the current values does not have to be waited for, which is particularly relevant when the rolling mill accelerates or decelerates. In the steady state of the rolling process, the calculated sensitivities ensure that the flatness control is optimally adapted to the product or material.

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.