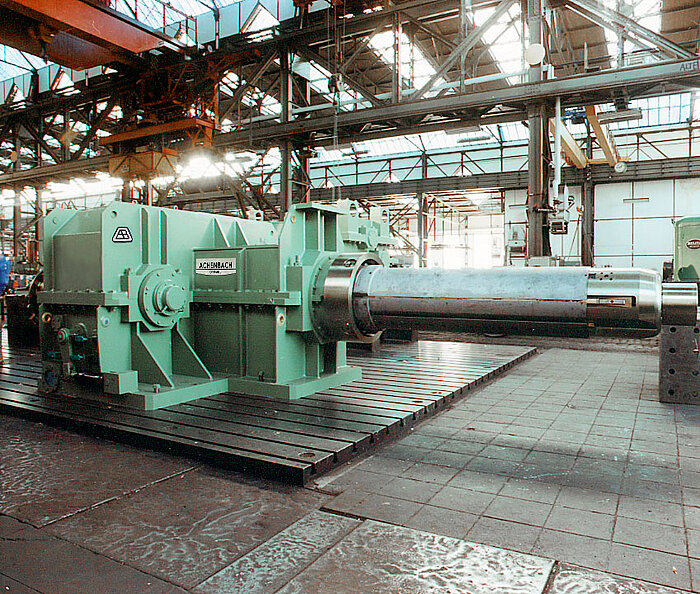

Our long-standing customer COMPANHIA BRASILEIRA DE ALUMÍNIO from Brazil has placed an order for the modernization of two Achenbach rolling mills with us. The two rolling mills will be upgraded to the latest technology.

This includes a new roll setting system, a new Achenbach UniSpray® Coolant Distribution System for high-precision application of the rolling oil in combination with the Achenbach UniFlat® Flatness Measuring Roll for optimized strip flatness control. These are complemented by an Achenbach OPTIROLL® i3 package for rolling mill automation with efficient model-based control functions such as a high-precision strip thickness control (Mill Gauge) and a highly dynamic strip flatness control (Mill Flat).

With this modernization COMPANHIA BRASILEIRA DE ALUMINIO wants to achieve the goal of maintaining the performance and availability of the mills in the future.

We are grateful for the 60 years of partnership and look forward to working with COMPANHIA BRASILEIRA DE ALUMINIO again.