Achenbach OPTIFOIL®

Doubler

ACHENBACH OPTIFOIL®

Doubler

Doublers process two foils as preparation for the last rolling pass in the production of thinnest aluminium.

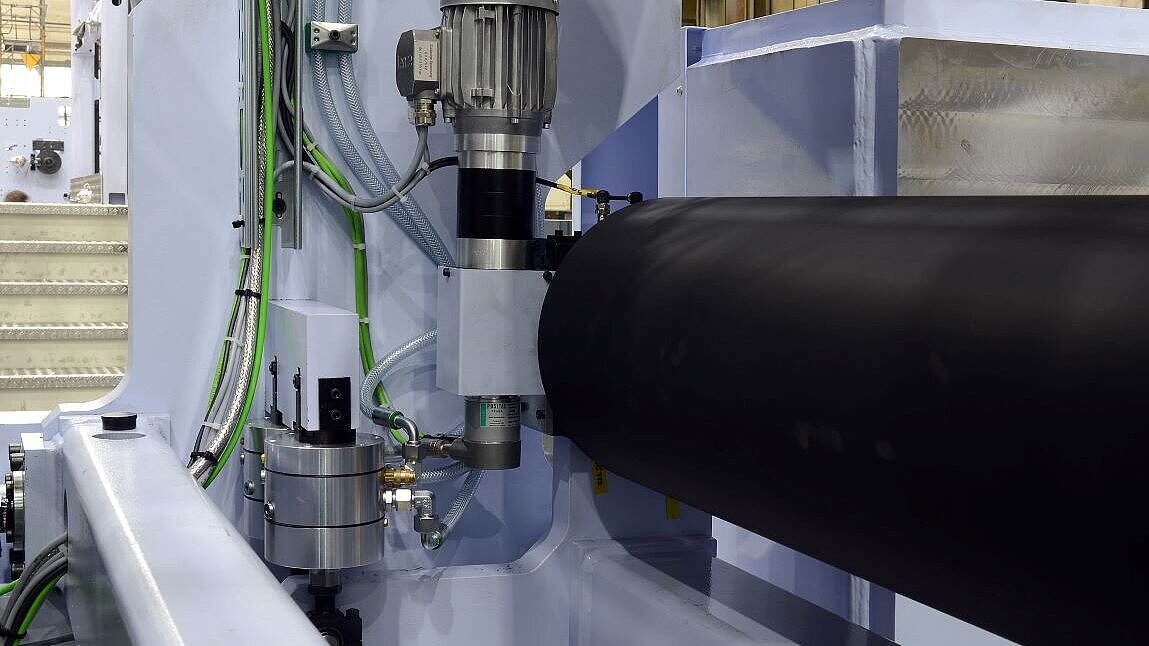

Dynamically adaptive and highly precise spraying device

Functional light-weight housing with integrated fully automatic material handling

Hydropneumatic pressure system with innovative double diaphragm cylinder

Rewinder operation with integrated trimming

Achenbach OPTIFOIL® Doubler

Rewinding diameters

Speeds

Coil weights

Foil thicknesses

A holistic approach.

They are always tailored to the specific purpose.

For each new doubler or those to be modernized, a holistic approach to perfectly synchronize mechanics, hydraulics, automation, and drive technology in their complex interaction is applied.

Achenbach OPTIFOIL® Doublers consist mainly of two coil deposits for material access, a cart, two unwinding stands, a roller bridge with a material feed device, a spray unit with suction for separating oil application, a shear or razor trimming device, a winder, and a spool cart for transporting the empty reel from the unwinding stations to the winder. Each doubler features very short material transport paths.

A variety of useful automation and process engineering options allows the system to be easily adapted to individual customer requirements. Examples of this include the simultaneous transport of two coils for unwinding or different coil and reel handling systems; these options can be added anytime.

- Functional light-weight housing with integrated fully automatic material handling

- Hydropneumatic pressure system with innovative double diaphragm cylinder

- Rewinder operation with integrated trimming

- Double coil car for material threading

- Dynamically adaptive and highly precise spraying device

- Extended threading device

- Efficient oil mist exhaust system with optional oil recovery

Contact us directly. Our team is available for you.

To move forward in a modern economy, we need to step up the speed together.